Producing high quality custom semi-products of metal and plastic

We are the leading worldwide OEM manufacturer that delivers premium quality products for our clients

Customer Needs

Integrate customer needs and streamline the process of managing suppliers and processes.

Process Analysis

Shin Kao has an international engineering team to accelerate the communication with customers and provide the best solution quickly.

Design Analysis

Our engineering team has experience in metal, plastic, mechanical and R&D technical understanding. These capabilities include self-opening mold and production, to research and development test mode, providing product development suggestions, value engineering and developing exciting new product lines using cutting-edge industry machineries.

Product Procurement

Shin Kao sources high quality raw materials and components from reputable suppliers to meet client’s standards.

Mold Development

Complete mold manufacturing process, from in-house R&D to mass production while achieving high quality and competitive pricing.

Engineering Technology

Shin Kao has over 40 years of engineering experience in automation equipment, mechanical manufacturing, 3D design, precision machining, surface treatment, forming, die casting, stamping and plastic injection molding.

Prototyping

Shin Kao has the ability to do prototyping to help improve product quality and efficiency in mass production.

Quality Inspection

Rigorous quality control processes at every stage of production to meet client’s particular FAI/PPAP/RoHS requirements through the use of industry leading QA equipment.

Warehousing and Shipping

Shin Kao plans, control and guarantees the delivery of your parts from factory to destination. We ensure that your inventory is secure and available after production.

Customer Service

Every stage of production will be communicated in detail to ensure timely responses to customer requests and effective communication.

Sample list of our iso facilities manufacturing capabilities

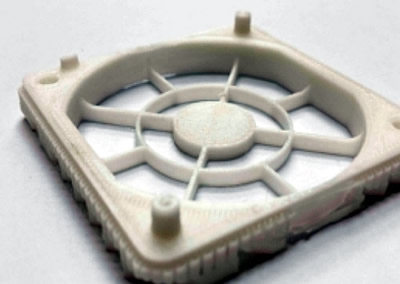

3D Printing

Anodising

Assembly

Automated Polishing

Automated Powder Coating

CNC Machining

Die Casting

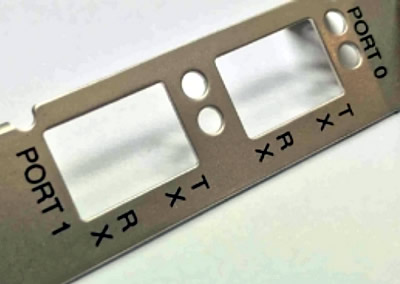

Laser Engraving

Plastic Injection Molding

Prototype

Sand Blasting

Silk Screening Pad Printing

Stamping

Tooling

Welding

Wet Painting